Signage today comes in many shapes, sizes and often most importantly – prices. The number of various printing technologies available today make it possible for the sign industry to offer numerous selections to find the right solution for businesses.

Wide format printing technology has opened up the possibilities to sign shops and clients by providing better solutions for numerous printing surfaces and ink. The challenge for those looking to have signage created is understanding the difference the different types of wide-format machines offer and what services can be produced by wide-format printers.

What’s the difference?

What’s the difference?

Wide format printing devices –for the most part –are designed to perform a certain function. Some printers are designed for faster throughput, others for a particular customer need such as output quality or width; and some are designed specifically to work with a particular type of ink technology.

The Ink Types

Solvents Ink

Solvent, and more common today, eco-solvent, is the most widely recognized ink technology used in wide-format printing. This type of ink is versatile, durable, vibrant, and can adapt to the characteristics of the material used as a surface. PVC-based materials are used frequently with solvents because of how well they work together. Typically, vehicle wraps and graphics including decals and magnetics are solvent based prints, as well as traditional banners. Solvents can also be used in T-shirts and in areas where it is exposed to heat due to the ink’s durability and resistance to extreme measures.

UV Curable Ink

UV Curable Ink

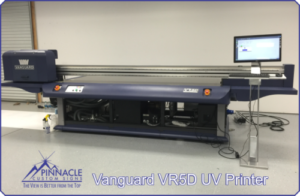

UV curable inks are used on flat surfaces and are “baked” under lights that cure the ink to the surface. In recent years’ new technology has allowed UV inks to be cured at different rates in order to create different finishes such as spot gloss and matte. UV curable inks are typically used on interior signage and can be used in exterior prints but over lamination is recommended to prevent chipping. The ability to print with UV regardless of base color makes this process attractive to many printers. Apply UV Inks to flat surfaces such as corrugated plastic and PVC is most common but it can be applied to polycarbonates, polystyrenes, synthetics, and more exotic surfaces such as woods and metals. Today this method can be used to produce interesting effects on things such as mobile devices, keys, and glass surfaces.

Latex Ink

Latex Ink

The final type of ink is latex. Latex ink technology is still fairly new in the wide format market, but offers some uniqueness. Latex is regarded as a ‘green’ ink due to its water-based composition. However, compared to other technologies latex ink requires heat to cure. One advantage is the inherent flexibility of the ink, making it compatible with many different surfaces including some uncoated fabrics. However, latex does not fare well in exterior environments and require over lamination of the product. Latex is also water-based so it doesn’t sustain direct sunlight well. Latex does work well on fabric and canvas applications such as pole banners, table skirts, and can be used well with vehicle graphics by combining the over-lamination process due to its flexibility.

Now you Know

Working with a printer who has experience and can guide you in finding the best surfaces, inks, and printing process for your project is ideal. Pinnacle has experience in all of these process and can answer any questions you may have about using the right ink to match the goals of your next signage needs.